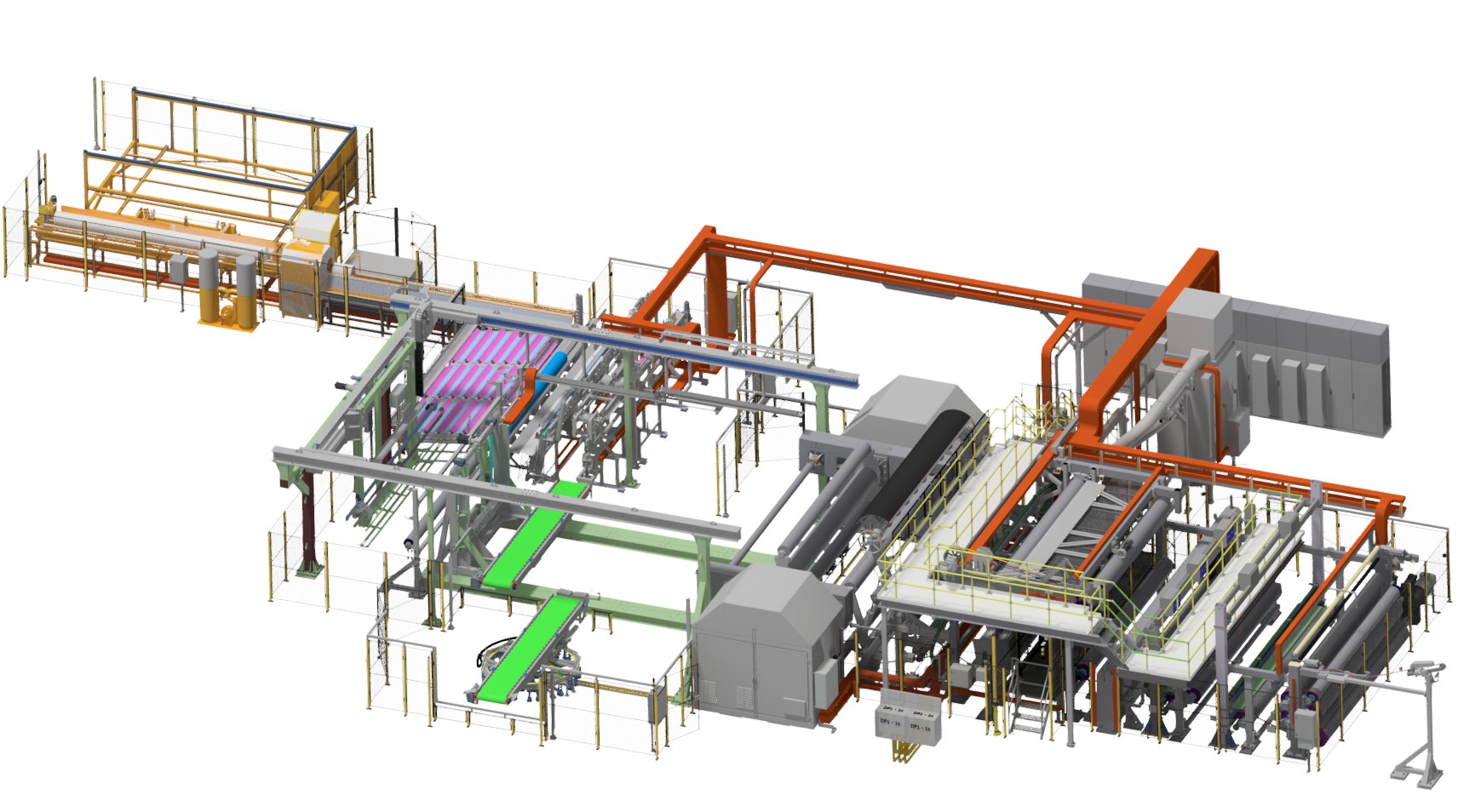

Jumbo Winder – High-Performance Winding System for Glass Mats & Veils

The Jumbo Winder is designed for continuous controlled winding, inspection, and both cross and longitudinal cutting of glass mats and veils. Positioned at the final stage of the production process, it ensures precise tension control, optimized roll formation, and automated handling, all tailored to meet your specific production needs.

Our winding systems are fully customizable, ranging from a basic winder configuration to a fully automated layout, including integrated roll and shaft handling, packaging, and synchronization with downstream technology.

Key Features & Advantages

- Modular design, supporting one- or two-operator systems depending on automation level.

- Flexible shaft diameters for various core sizes.

- Short automatic cycle time – cut-to-cut, including manipulation, can be completed within 4.5 minutes.

- Fully automated roll handling, ensuring seamless production flow.

- Industry 4.0 integration – featuring auto-diagnostics, preventive maintenance, and Siemens Simatic & Sinamics control systems.

- Enhanced safety measures, including Safety PLC and compliance with EU & OSHA standards.

- Optimized machine footprint, offering compact design and improved safety.

- Advanced threading rope system with high-security threading for 6"–12" cores.

- Next-gen safety chuck for jumbo rolls – ensuring longer service life, robust functionality, and quieter operation.

- Automated longitudinal cutting and trim removal, with integration options for dust extraction.

- Non-stop winding – designed for 6"–12" shafts (paper cores), allowing quick shaft-size adjustments.

- Precision-controlled compensator system, ensuring uniform tension distribution and extended roller surface life.

- Integrated roll, shaft, and core handling, supporting automated and manual core insertion, wrapping line synchronization, and adhesive start solutions.

Since each Jumbo Winder is specifically designed to match your production parameters, we welcome discussions to tailor the perfect system for your operation.

Technical Specifications

-

Maximum web width – Up to 5,500 mm (216")

-

Maximum roll diameter – Up to 2,500 mm (98")

-

Maximum winding speed – Up to 500 m/min (1640 FPM)

-

Shaft diameters supported – 6", 8", 10", 12"

-

Cycle time (cut-to-cut) – 4.5 minutes

-

Integrated automation – Fully automatic roll handling & shaft puller

-

Compliance & safety – EU Machinery Directive, OSHA 1910.23, ISO Standards